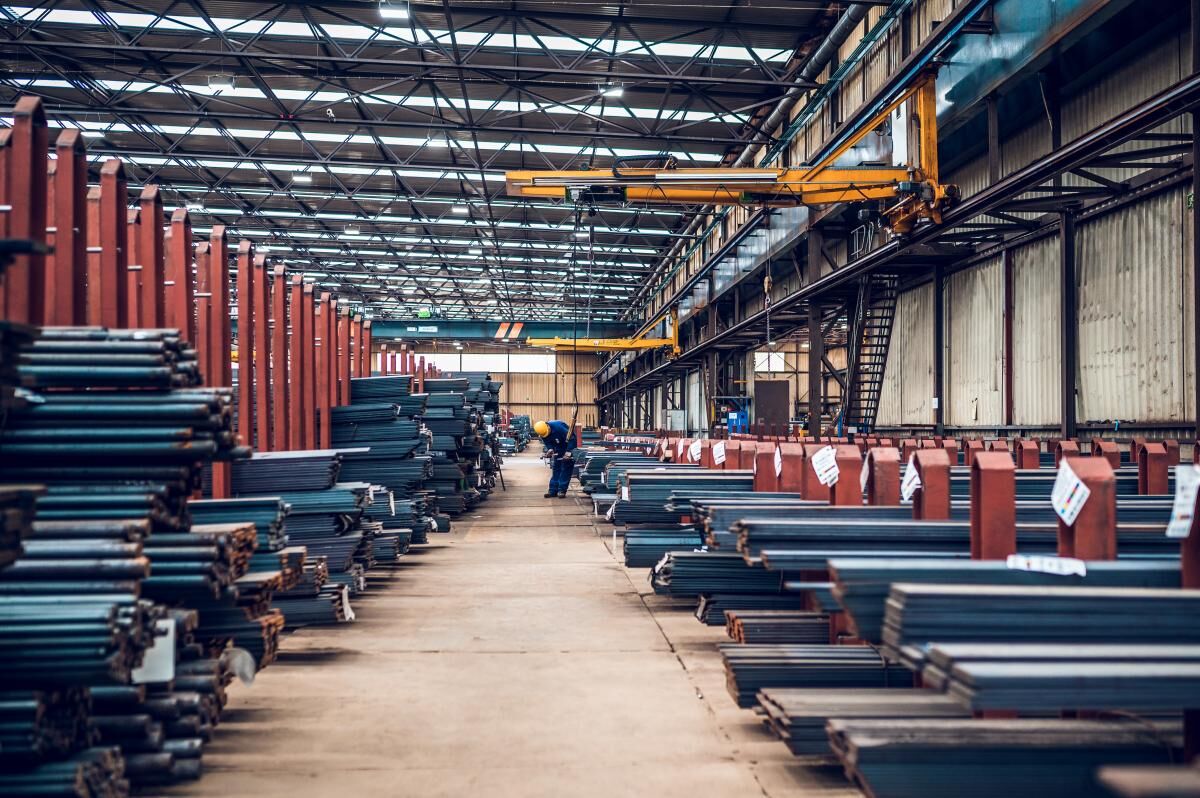

Digital certificate traceability

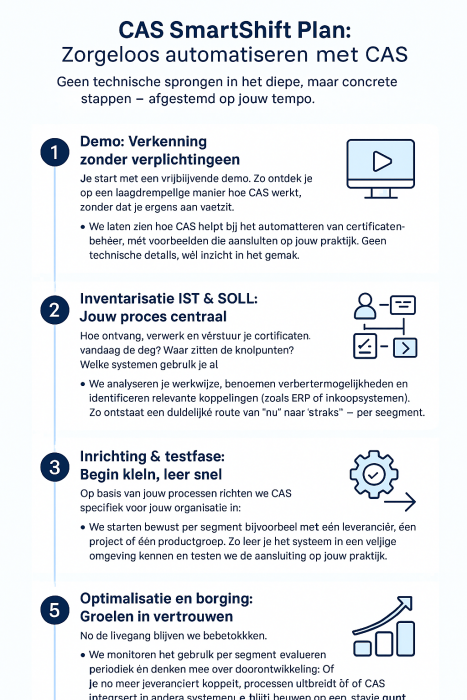

- Quality assurance

- Time and Cost saving

- Traceability

- unique advantages for your customer

The role of the material certificate in the steel industry is changing. Among all our customers, we are seeing growing pressure in relation to the information provision about materials, and that pressure is set grow and intensify further in the future, also in response to regulatory burdens from government and other parts of the supply chain. More and more clients and fabricators are requesting certificates to accompany their purchases, with a view to including safety, demonstrable quality and traceability. How can you remain competitive in such a competitive market? Digitalisation is essential to safeguarding the continuity of your organisation.