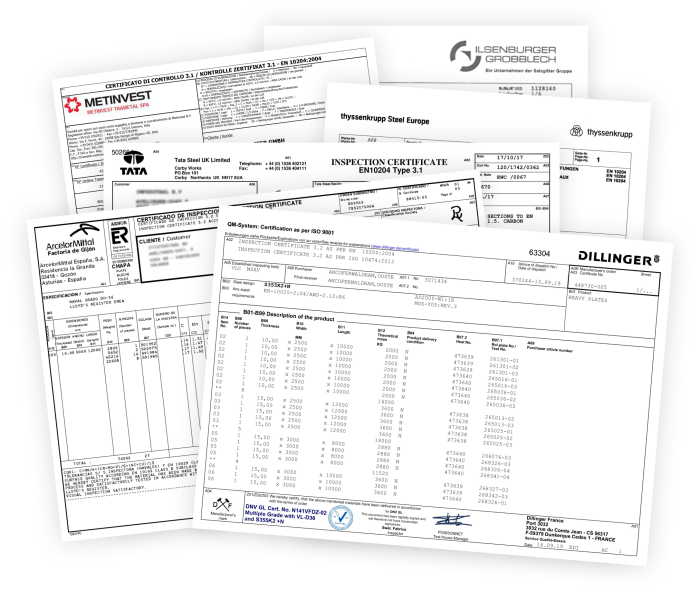

Digital certificate traceability

- Quality assurance

- Time and Cost saving

- Traceability

- unique advantages for your customer

As a steel fabricator, your work is closely scrutinised. The provision of information about materials is subject to an ever growing number of rules and regulations, and that scrutiny is set to be further intensified in the future. Traceability and complying with standards and requirements can help guarantee the continuity of your organisation. To achieve and maintain that level of quality, digitalisation is unavoidable. By combining project information with certificate information supplied by CAS, you are able to quickly and simply enhance the data book that accompanies all your fabrication projects, with the original material certificates. As well as massively improving efficiency, this also helps further modernise your organisation!