‘”CAS is of huge value to us. We have more than 40,000 tonnes of steel sheets on stock. You can’t tell the quality or chemical composition of a sheet just by looking at it. For us, CAS means quality, security and traceability, throughout the process.”

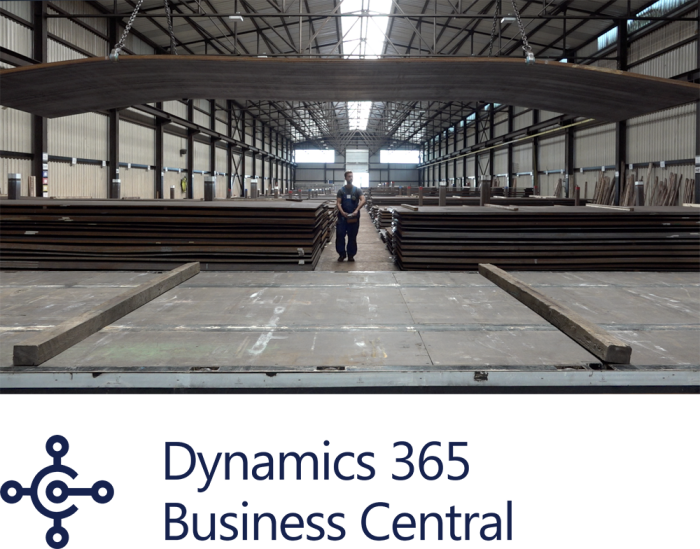

An absolute first! CAS was used for the first time at Stigterstaal, the leading suppliers to the maritime industry. In fact, CAS was born at Stigterstaal. With a clear focus on optimum quality, Stigterstaal collaborates with a number of partners. They supply (processed) steel sheets to their customers. Every sheet comes with a certificate, that contains a whole series of data, including the chemical values. And those details are very important, because not every steel type can be used in every application. Certainly not in shipbuilding.

For more than 60 years, this family-owned business has been the leading steel supplier for shipbuilders, ship repair yards and offshore fabricators, not just in the Netherlands but far beyond. Thanks to solution-driven working methods, a no-nonsense mentality and shipbuilding steel of superior quality, they have become a leading supplier of steel for the shipbuilding and offshore industries.

Because quality is so important, we work together with a number of partners, each with their own specialisation. Stigterstaal serves as the agent, perfectly translating the customer’s wishes. They then outsource the various processes such as painting, cutting and shaping. “Only by bringing together the full range of specialists can you guarantee your customer precisely the service they need. Only the best will do,” explained director Gerben Cozijnsen.

In the past, linking the certificate to the steel sheet involved a complex, time-consuming, manual process. The complexity of the process could easily lead to mistakes, which meant that the certificate was no longer easily traceable. When a customer turned up to collect his order, and was forced to wait around with the engine running and the clock ticking, the result was huge frustration for both the customer and our workforce. Thanks to CAS, an innovative software application, this process has now been fully digitalised, which offers huge advantages to all parties.

‘”CAS is of huge value to us. We have 40,000 tonnes of steel sheets on stock, and you cannot tell its chemical or mechanical values, just by looking at it. When you realise that a customer is working on a specific project, that requires a specific set of values, then it is extremely important to us that we have made a clear record of all the requirements, in our system. The system then enables us to select the appropriate sheet material quickly and with relative ease, so they can be delivered to the customer, as soon as possible. Thanks to our use of CAS, we are able to supply the certificates we receive from our factories in perfect order, direct to our end users.”

Because the steel sheet is stored in different batches, the material certificate is a vital element of this process. Gerben continued, “The steel that we use and that is subsequently processed has to satisfy predetermined requirements. And those requirements are specific and unique to each customer and each application.” For Stigterstaal, it is essential that the processes run quickly and smoothly, so the customer is always guaranteed good quality and correct deliveries. “You first need to know the values of a steel sheet before you can do anything with it. If those details are automatically entered in your system, the whole process becomes far more efficient,” explained Gerben.

In the past, the data were not automatically entered in the system. Before CAS came on the scene, linking the material certificate was a complex manual process. “When the steel sheets were delivered, we had to work through a whole series of tasks. First of all someone examined the sheet for the sheet number and even that was sometimes a difficult job in itself. The number was then written down, and passed on to the office. Once there is was added to the pile of paperwork listing the various numbers that had to be linked to the certificate,” went on Gerben, with a sigh. “All that paperwork is a disaster waiting to happen, and backlogs are almost inevitable. On occasion, mistakes happened with the wrong sheet being selected. It was not until the certificates were linked that you discovered you had the wrong sheet and the whole process had to be started over.”

Thanks to the smart application from CAS, Stigterstaal is now able to automatically identify and link the certificate to the correct steel sheet. “We are now able to easily and quickly identify in our ERP system (...) which certificate matches the customer’s wishes,” explained Gerben. “We then pass on that information to the warehouse and the warehouse staff know exactly which sheet to pick.”

Commercial manager Gert van der Velden added, ‘”CAS is of huge value to us. We have more than 40,000 tonnes of steel sheets on stock. You can’t tell the quality or chemical composition of a sheet just by looking at it. For us, CAS means quality, security and traceability, throughout the process.”

CAS developed a special certificate portal for Stigterstaal, that runs flexibly and efficiently. In Gert’s words, “The certificate portal is an easy-to-us tool in which we place all the certificates for a sales order or project, in a single location. And our customers have access to all those records, at any time. The whole process now runs faster and more easily, not only for us but also for our customers.”

The cooperation between CAS and Stigterstaal is remarkable, in that it in fact led to the establishment of CAS itself. “It all started around 5-6 years ago,” explained Gerben. “The process of linking certificates to the metal sheets was often a cause of irritation and much lost time. We agreed there had to be a better way.” Having identified the problem, Gerben approached a software company. “Unfortunately, the people we called in were unable to create the solution we needed, but Bastiaan, the founder of CAS, was convinced that a solution could be achieved. Together with us, he worked on perfecting the partly developed software system.”

As well as its remarkable origin, the cooperation between us has always been pleasant. In Gert’s words, “They are friendly, open people and we felt the chemistry, right from the start.”

For the time being, CAS does everything Stigterstaal needs it to do, but there are already new plans for the future. Gert concluded, “I am often in touch with Koos, the director at CAS. We discuss the way the market works, and how we can perhaps be of assistance to each other, in the future. For the time being, everything is working perfectly.”

We are happy to share our knowledge. Leave a callback request and we'll get back to you