Jonathan Jacobus - Manager Quality Control

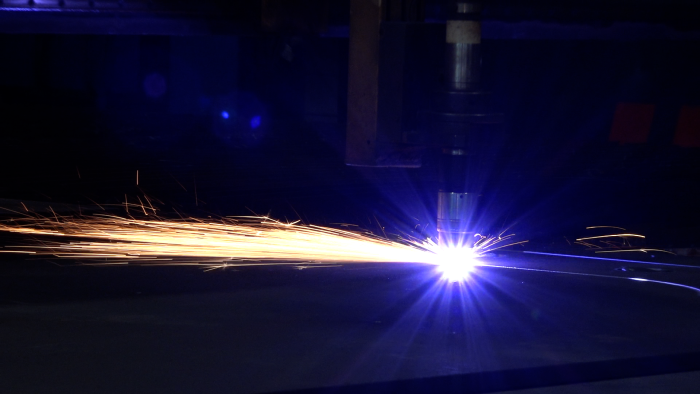

The family-run business Joop van Zanten Staalservice, specialists in processing sheet steel, deals with large numbers of steel sheets every day. To be able to guarantee their customers that they will receive the right steel sheet, all steel sheets must be traceable according to a unique number, linked to a material certificate. In the past this task not only took a great deal of time but also entailed the risk of human error. To solve these issues, the company recently introduced CAS: an innovative software application for the digitalisation of material certificates.

Joop van Zanten are all-round suppliers for processing steel sheets thanks to their ability to cut steel sheet also ‘in the thicker steel segment’. Joop van Zanten is also the perfect address for a whole range of finishing processes such as brake pressing, alignment and bevelling. This family-owned business, that has been operating in the sector for decades, is constantly forward looking. ‘We always operate according to the state of the art. Today’s market demands both flexibility and speed, combined with reliability and quality,” said Johnathan Jacobus, team leader at the purchasing department.

“We are increasingly investing in technology, to enable us to continue to serve our customers quickly and expertly, now and in the future. Currently we are working to digitalise our processes. Our aim is to combine all the knowledge from all the departments in a single online environment so that it can all be made available at any time, to anyone in the organisation. After all, access to information will improve our ability to deploy our expertise.”

When it comes to digitalisation, Joop van Zanten Staalservice regularly comes up against new challenges. One such challenge was linking material certificates to steel sheets. “Material certificates are very important for us,” continued Johnathan. “After all, material certificates enable us to demonstrate that we only supply quality products. All the steel sheets that arrive at our business are traceable according to a unique number linked to the certificate.” That is important because it means you always know from exactly which sheet a product is cut. He further explained, “This material certificate provides the customer with all the specifications relating to the sheet material: the manufacturer, the chemical value and composition of the material.”

Until recently, linking material certificates to individual steel sheets was a labour-intensive task, that demanded absolute precision from our workforce. “In the past, we always had to manually link the material certificates as soon as a steel sheet was delivered to our factory. To complete this task, one of our employees had to make the time to check the material type, compare it with the order for a correct match, and record the details manually in a folder, which then had to be put in the right location so that the sheet material and the relevant numbers could be linked together. Correctly recording all those details was a time-consuming process. And that meant losing a great deal of valuable production time.”

For Joop van Zanten Staalservice, the innovative software application CAS proved the perfect solution. Johnathan explained how it works: “CAS automatically recognises the heat number and sheet number of the material, the material type and the thickness. The software then matches the material certificate to the steel sheet. All these details have been entered in advance, and ‘learned’ by the system.” If the data are not recognised there is no match. Thanks to CAS, we can now always guarantee that the right steel sheet is put into production.

During the implementation process, a great deal of attention was paid to the system structure. “CAS helped us analyse the problem and examined our process in detail. They even included the link to our ERP system Ridder IQ, as part of the implementation process.”

Now that implementation has been completed, Joop van Zanten reaps the benefits of the application, every single day. “Thanks to CAS, at the touch of a single button, we can now link the material certificate to the steel sheet. It saves us a huge amount of time and eliminates the risk of human error. That combination offers our customers the certainty that they will receive the right certificates, with the right product.” It also eliminates unnecessary waiting times so that the steel sheets can go straight into production the moment they are delivered.

Cooperation with CAS came about in a somewhat unexpected manner. “In fact CAS came to us,” explained Johnathan. “As soon was we realised that they could solve our problem with waiting times, we were hooked. This was precisely the solution we needed.”

Looking back, he is more than satisfied with the cooperation. “We are always somewhat dubious when it comes to software suppliers. Can they actually live up to their promises? CAS, however, has exceeded our expectations. They are a reliable partner, and our contact is excellent. They did exactly what they promised to do and even now, following implementation, they continue to monitor developments.”

For the future, too, Johnathan sees further opportunities for cooperation between Joop van Zanten and CAS. “We have already asked CAS to assist us with more digitalisation issues. Without doubt it is the start of a long-term relationship.”

Want to see CAS live? You can! We would love to show you how to stay ahead in the steel industry